Their sequence depends on a bewildering number of factors (2016)

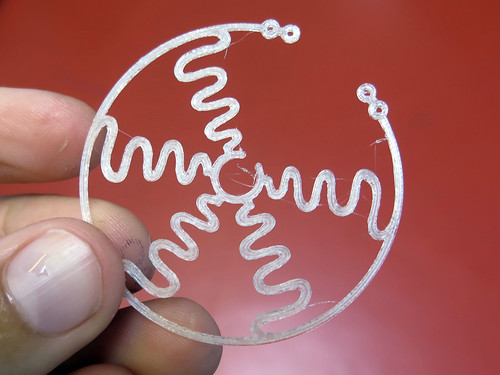

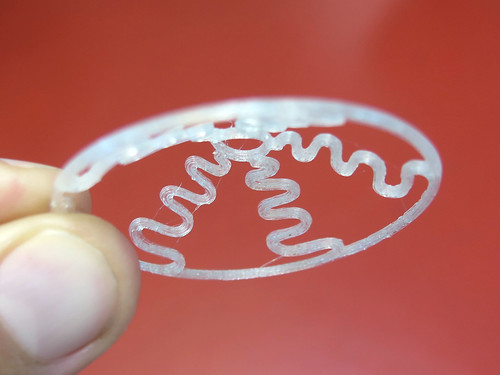

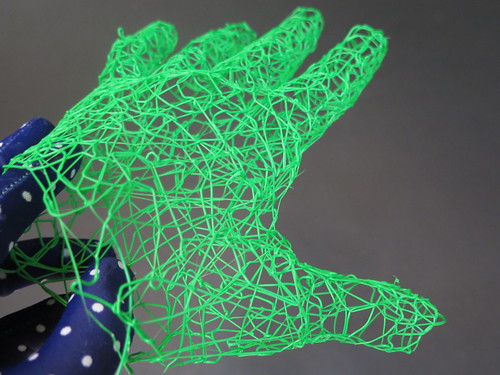

The following specimens were collected during a 4-month expedition through Autodesk Pier 9‘s CAD/CAM software packages, CNC work-flows and machine shop.

>> Photos

All italic text on this page was taken from the Autodesk machine shop basic use manuals, the CNC pathway handbook and the Voxel8 support documentation.